Brake Hose & Fittings

When selecting components for hydraulic systems in marine applications, the use of stainless steel hoses is essential for ensuring durability and resistance to corrosion.

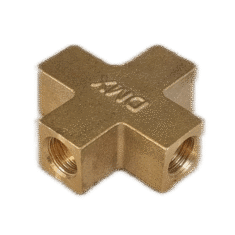

These hoses are often paired with high-quality brass fittings, which provide a reliable connection that can withstand the rigours of trailer transport and marine environments.

The combination of stainless steel and brass not only enhances the longevity of the hydraulic system but also maintains optimal performance under varying pressures.

Installation

Proper installation and regular maintenance of these hoses and fittings are crucial to prevent leaks and ensure safety during operation.

Additionally, choosing the right size and specifications for the hoses and fittings is vital to achieving efficient hydraulic flow in both trailer and marine settings.

Using reinforced hoses can further enhance the system’s resilience against abrasion and environmental factors.

It is advisable to regularly inspect the fittings for signs of wear or corrosion, as these can compromise the system’s integrity.

Furthermore, employing protective sleeves or covers can offer additional safeguarding against potential damage from external elements.

Training personnel in best practices for handling and maintaining hydraulic systems can also contribute significantly to operational safety and efficiency.

Ultimately, investing in high-quality components and proper maintenance routines pays off in improved performance and reduced downtime.