NSK

NSK (Nippon Seiko Kabushiki Kaisha) bearings are popular for their century-long reputation for Japanese engineering precision, extreme durability in harsh conditions, and their position as the world’s third-largest bearing supplier.

Several key technical and market advantages drive their popularity:

- High-Precision and Specialised Steel Material Quality: NSK uses proprietary “high-purity” materials such as Z-steel, vacuum-refined steel (VAR steel), and EP steel (ultra-long-life, high-reliability steel) to minimise impurities that cause fatigue.

- Nano-Level Accuracy: Their bearings achieve ultra-high precision, limiting rotational errors to the nanometer level, which is critical for high-speed dental drills (400,000 RPM) and hard disk drives.

Industry-Specific Reliability

- Railways (Shinkansen): NSK has supplied bearings for every generation of the Japanese Shinkansen (bullet train) since 1964, demonstrating a proven track record for safety and high-speed reliability.

- Electric Motors & Robotics: They are the preferred brand for applications requiring low noise and low vibration, making them dominant in electric vehicles (EVs), robotics, and CNC machines.

- Extreme Environments: The SPACEA™ series is designed for extreme conditions like outer space, vacuums, and high-temperature medical scanners.

Innovation and Extended Service Life

- Longer Life Cycles: In 2025, NSK remains popular for its HPS (High-Performance Standard) series, which offers up to double the service life of conventional bearings by using advanced cage designs and heat treatments.

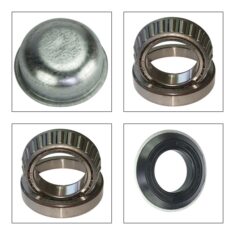

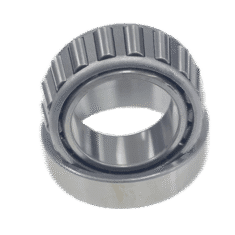

- Low Friction & Sustainability: Recent developments, such as the 7th-generation low-friction tapered roller bearings (2024), reduce energy loss by 20-80%, contributing to better fuel efficiency in vehicles and lower carbon footprints for industrial machinery.

Market Accessibility and Support

- Global Presence: With over 200 business locations in 30 countries, NSK provides fast replacement parts and technical support worldwide.

- Cost-Effectiveness: While often having a higher upfront cost than budget brands, their longevity makes them more cost-effective over time by reducing maintenance intervals and downtime.

These technical guides compare NSK and SKF bearings and explain NSK’s advanced life prediction methods for increased durability: