10-inch Electric Drum Brake Conversion Kit | Trailers, Caravans & Campers

Easily change your unbraked or disc-braked trailer axle to electric drum brakes.

Electric brakes are reliable, safe, and easy to maintain. Similar to backing plates seen on cars, electric drum brakes use backing plates to apply brakes. Even better, 10″ drum brakes are one of the most common brake systems on Australian trailers and caravans, meaning that finding spare parts is easy.

Couplemate™ 10-inch Conversion Kits are available in multiple stud patterns, such as 6-Stud Landcruiser and 5-Stud Ford.

For increased 4WD performance, you can upgrade to Off-Road Brakes.

Why do people like electric trailer brakes?

Along with being cheaper than disc brakes, people like them because they:

- Prove highly effective, safe braking in all-terrain conditions.

- They are low maintenance and require no technical knowledge.

- Spare parts are relatively cheap and easy to find anywhere in Australia.

- Use brake controllers that allow you to adjust power output if needed easily.

Conversion Kit Contents

The Couplemate™ Conversion Kits are designed to easily convert your current axle to electric brakes.

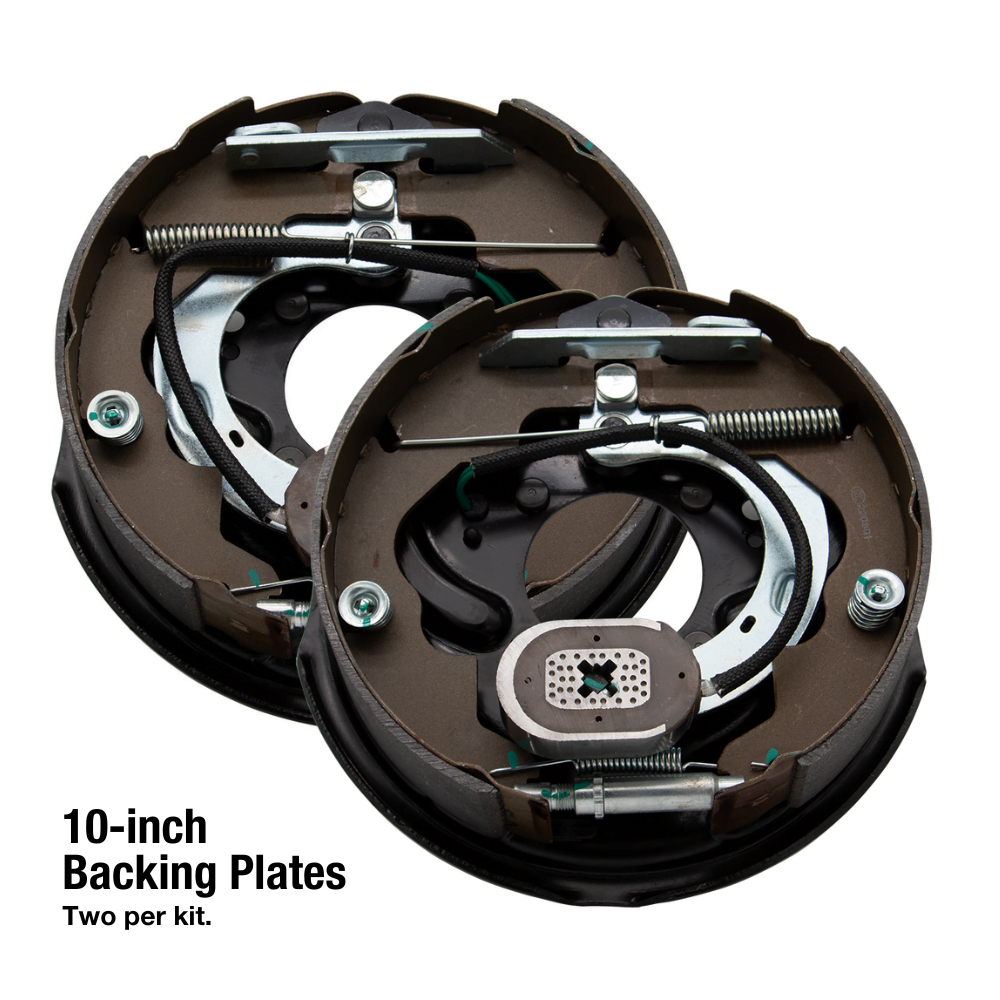

When you buy this conversion kit, you will receive:

- 2 x 10″ Brake Drums (incl. wheel nuts)

- 2 x 10″ Electric Backing Plates (incl. mount nuts)

- 2 x Japanese Bearing Kits (incl. bearings, seal and grease caps)

- 2 x Weld Rings

What are the Weld Rings for? Weld Rings get welded onto your axle and allow you to mount your backing plate.

What Parts Do You Need?

Bearing Profile

This information is sometimes outlined in your owner’s manual or kept on file by the original caravan/trailer manufacturer. However, most customers resort to a hands-on approach.

To find your bearings, separate your hub from your axle and pull out both bearings. Quality bearings will always have their bearing number engraved on them, as shown in the example image:

Holden LM Bearings (750kg)

- Inner Bearing: LM67048/10

- Outer Bearing: LM11949/10

Ford SL Bearings (1450kg)

- Inner Bearing: LM68149/10

- Outer Bearing: LM12749/10

Axle Weld Rings

Firstly, examine the bearing profile to determine whether a marine or electric turn weld ring is required for your axle.

Not sure? Measure from the tip of the axle to the back shoulder.

- Electric Turn: 128mm

- Marine Turn: 115mm

If you have a marine turn, use square. If you use an electric, use a round.

View Electric and Marine Axle Profiles

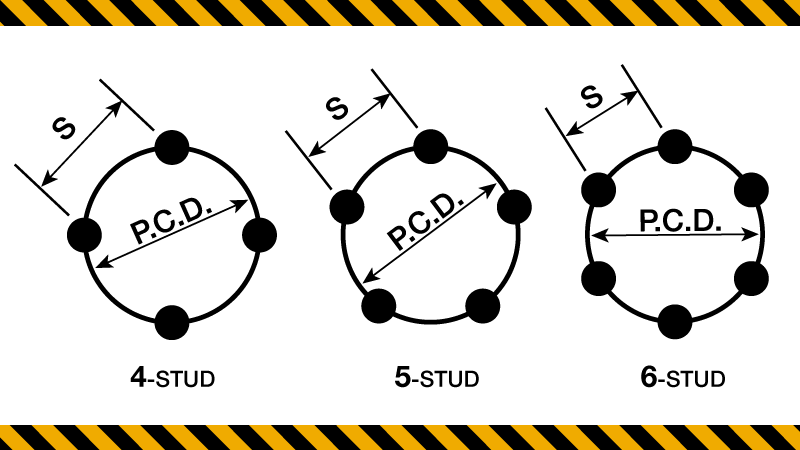

Stud Pattern & Stud Thread

Understanding your Stud Pattern (PCD) is crucial when buying spare parts, as it ensures that your new drum will fit your existing trailer wheel.

The best way to work out your stud pattern is by measuring from stud centre to stud centre on the two closest studs (see “S” on the diagram). Once you have this measurement, use our Stud Pattern chart (available here) to work out your PCD.

How To Install Electric Brakes

Method One

When fitting your electric weld ring, ensure pressure against the rear shoulder and quickly tack the four corners. You are now ready to weld the weld ring into place.

Couplemate uses a tool to firmly secure the weld ring onto the axle shoulder before tack welding.

Method Two

- Bolt the weld ring to the backing plate

- Slide the backing plate onto the axle

- Install the drum onto the axle and tighten it (no grease in the bearings at this stage).

- Pull the backing plate into the drum and tighten the brake shoes to engage the drum firmly.

- Tap the backing plate so it is Concentrix with the drum

- Tighten the shoes against the drum firmly

- Tack the backing plate on the four corners

- Remove the drum

- Finally, finish the weld and repeat at the other end of the axle.

What’s Good About Couplemate™ Drums?

Our engineers successfully addressed a critical issue, “porosity,” significantly contributing to braking inefficiencies.

Porosity refers to the presence of small holes within a casting, which reduces brake shoe adhesion. Essentially, a porous surface exhibits lower braking resistance than a non-porous surface.

The most effective method to eliminate air from steel is analogous to expelling air from concrete. By subjecting the tooling containing a drum casting to shaking or vibration, we effectively eliminate air bubbles, significantly reducing the occurrence of porosity.

Furthermore, our skilled craftsmen meticulously scrutinise the machining process for any signs of porosity. When identified, drums are promptly rejected, discarded, and returned to the furnace. This stringent quality control ensures that the drums you acquire have undergone rigorous testing and inspection processes, guaranteeing their performance and reliability.

Additional information

| Weight | 34 kg |

|---|---|

| Dimensions | 35 × 35 × 60 cm |

| Stud Pattern | 5S Landcruiser (150mm), 6S Landcruiser (139.7mm), Commodore (5 x 120mm), Ford (5 x 114.3mm), Holden HQ (5 x 120.65mm), Holden HT (5 x 107.95mm) |

| Select Weld Ring | No Weld Ring, Electric – 40mm Sq Axle, Electric – 45mm Rnd Axle, Electric – 50mm Rnd Axle, Electric – 50mm Square Axle, Electric – 50mm Square Hole, Marine – 40mm Square Hole, Marine – 45mm Square Hole |

Our Service Lifetime Warranty

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure and compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

Couplemate™ is a manufacturer and vendor of high-quality towing, trailer, and caravan components. Couplemate™ Core Goods and Custom Work are guaranteed to be free of defects for the service lifetime of the product when used as intended.

Warranties are non-transferrable and Couplemate™ requires satisfactory proof of purchase prior to issuing a remedy. The full Couplemate™ Warranty Policy can be found in the Terms & Conditions: Section 8 – Consumer Guarantees & Warranty.

Warranties are in addition to your rights under the Australian Consumer Law. If something is wrong with your order, please contact our team.

60-Day Returns

After 60 years of experience, we know that life has its unpredictable moments.

All Couplemate™ orders (online, over the phone, or in-store) have a 60 day period for change-of-mind returns and exchanges. There are some items that can’t be returned and some returns may incur a 15% restocking fee.

You can view our full policy for change-of-mind returns here.

Reviews