Caravan and Trailer Wheel Alignment

A caravan wheel alignment service sounds complicated. How can the wheels on caravans and trailers become out of alignment?

It is common to find worn caravan tyres and wheel bearings in older caravans and trailers. A lot of kilometres, low tyre pressure, and shock loading are the prime causes of miss-alignment.

In a tandem axle setup, the rear axle suffers the most significant tyre wear. If you take the time to put a long straight edge across both tyres, I am sure you will be surprised!

Correcting the wheel alignment on a single-axle camper trailer is far easier than correcting the wheel alignment of tandem axle suspension systems.

Check out our axle triangulation guidelines document here.

How vital are axle pads?

How vital are axle pads?

Axle pads were first thought to align the spring on top or below the axle.

In many cases, axle pads have not been welded into position because many manufacturers did not require welding. U-bolts were thought to provide enough force to clamp the axle and spring into their correct location effectively.

Previously, we recommended that only round axles required welded axle pads. Read on to find the solution to how and why U-bolts cause misalignment and spring breakages.

U Bolts

Generally, U bolts installed on a caravan or trailer camper are made from mild steel. Mild steel stretches within the first 300 kilometres of installation and requires re-tightening.

Loose axle pads and loose U-bolts

Loose axle pads and loose U-bolts

Imagine driving down the highway west of the Great Divide, and you will no doubt have encountered a pothole or two.

A tow vehicle, caravan, or trailer entering a pothole at 100 kph causes shock loading.

Shock loading transfers massive forces that try to push your axle or axle group towards the rear of the caravan or trailer.

Unwelded axle pads may cause damage during continued driving.

What happens next?

Two things can happen to affect caravan or trailer wheel alignment:

- One wheel is now out of alignment. This alignment issue will produce significant wear on your tyres. If you have an overlay or drop axle, it may even have twisted the drop or overlay. Contact your dealer if your tyre wear is excessive.

- Loose-fitting U-bolts and axle pads will progressively cause the axle and spring assembly to fail. The beam will develop vibration, and the spring will eventually break about 75mm from the back eye.

Read an article on loose U-bolts and their effects here.

Axles without axle pads.

Axles without axle pads.

Couplemate dispatches dozens of axles daily. A small percentage of them have axle pads welded into position as requested by the customer.

The cost of an axle is between $600 and $1100.

If replacing an axle, provide your chassis width so we can weld your axle pads into position. The cost is $25.

Axle pads welded into position make your axle much more straightforward to install because the axle centres itself directly over the leaf springs.

This article assumes the chassis or frame is straight and true.

Independent Suspension

The manufacturer sets Independent suspension up for full load at zero camber.

Put a spirit level in the vertical position of the tyre. A gap of more than 5 mm is a concern.

Most Independent suspensions have a camber adjuster installed. Rigid suspensions, like the Couplemate ICS, do not require camber adjusters.

Loose Wheel Studs

A variety of factors cause loose wheel studs.

What causes Loose wheel studs?

Tandem Trailers

The best way to check your tandem trailer is to place a piece of straight-edge steel across the front of both wheels.

Call your service agent for an alignment if the tandem wheels are not square.

Finally, it is pretty likely that your U-bolts have come loose, and your rig has sustained some shock loading during your travels.

© Steve Wotherspoon 24th November 2018

Thanks Steve….. I think I will replace all the bushes, install new shockies (I see one is leaking) then check again. If still out I will get it done as I am not confident to weld axle onto plate.

Will head down to Wynnum to get shock absorbers etc and see how it goes.

Thanks again.

Roger.

Morning Steve.

I am scrubbing tyres on my tandem axle caravan and, following your advice in an earlier blog, checked alignment with a straight edge. I found the rear right hand wheel to be 20mm further back from the coupling point compared to the left hand side.

My problem is, how can I move it because the centre pin prevents movement. The centre pin is located into a plate welded onto the axle.

Should I just buy new springs as the van is 15 years old. It’s a light van (1680kg) and definately not over loaded.

Just discovered Couplemate and am really find your website helpfull,,,,Thank you. Regards Roger.

Hello Roger,

I see you have a tricky problem but it is easy to understand once I explain one solution.

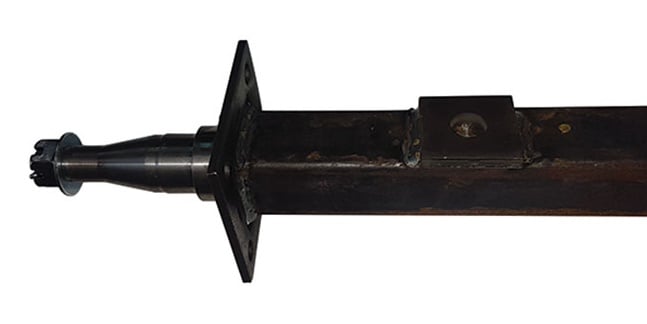

Remove the axle pad and replace it with a shackle plate.

1. Remove the current axle on the side that needs adjustment. Leave the other side u-bolts in place.

2. Insert the shackle plate hole over the centre pin.

3. Move the axle on the shackle plate until the axle is perfectly aligned.

4. Weld the axle onto the shackle plate.

This procedure will fix the triangulation mess you have encountered. Or the rear hanger has been installed incorrectly.

Alternatively, you can cut and move the rear hanger until it is square with the opposite rear hanger.

If you find this is too hard Roger, take it to your local caravan or trailer guys and he will fix it for you.

Thank you

Steve Wotherspoon

This is a prefect blog for who wants to know about lotus off grid caravan. Thanks for sharing this information.

Hello Adam and thank you for your comment. Steve Wotherspoon

Blair Stokes

Loose axle pads and loose u bolts

Driving down the highway, west of the great divide and no doubt you have found a pothole or two.

A caravan or trailer entering a pothole at 100 kph causes shock loading.

Shock loading transfers huge forces that try to push your axle or axle group towards the rear of the caravan.

If your axle pads are welded into position, you might not have noticed the damage and continue driving.

I think you meant If your axle pads are NOT welded into position

Thank you Alan, you are quite right. Fixed. Steve Wotherspoon