Why should I buy Electric Drum Brakes?

“But I do not think I need caravan drum brakes on my camper as it is a lightweight trailer.”

This is a comment that I hear regularly.

Case 1:

Imagine driving down a dirt road on a mountainside with a 2-tonne Landcruiser and a 750kg unbraked camper.

Braking for a corner, the Landcruiser slides on the dirt, pushed by your camper in tow.

You are quickly into the bend in the road, still on the skids, and you take the foot off the brake and power around the corner. I bet you have done that heaps of times.

OK, so you need caravan electric brakes right at this point.

Put a bit of rain on that same road, and it is 10 pm night-time, pitch black in the Daintree area. Very tricky.

Case 2:

Case 2:

You are towing the boat trailer from the Hawkesbury back to Brisbane, halfway down Cunningham’s Gap, and two semi-trailers are side by side.

You are only doing a slow 50 km/hr, but the trucks are going 20 km/hr.

This one scared me enough to put disc rotors and brakes on my boat trailer. I should have known better and done it years before, but I didn’t.

So What happened?

I locked all four disc brakes on the Landcruiser, and the front wheels were smoking. The boat was swaying, and I was heading toward the wrong side of the road as I could not reduce speed by 30km before I hit the back of the trucks.

Electric or disc brakes are a safety feature that gets you out of trouble on most occasions.

Too hard? Too expensive? If you don’t know much about brakes on trailers, then read on.

What are the major components of an electric backing plate?

- Shoe Compression Return Spring

- Actuating Arm (Magnet Arm)

- Shoe Hold-Down Spring

- Primary Caravan Brake Shoe

- Adjuster

- Adjuster Spring

- Electric Magnet

- Secondary Caravan Brake Shoe

- Backing Plate

- Park Brake Spring

- Park Brake Lever

What is a Drum Brake, and How do electric brakes work?

You need brakes on your camper if you are thinking about long trips.

If you need an axle fitted, lift your trailer with an easy jack and remove the axle. We will fit up and test your axle in our workshop.

The manufacturer or trailer repair centres usually install 10-inch Electric caravan conversion kits.

The weld ring (supplied) fits 125mm—139 mm from the axle’s tip to the weld ring’s front.

The weld ring will often fit on the last round machine surface and press hard against the shoulder (non-machined surface).

Axles up to 50mm Round or Square with Ford or Holden Bearings will accept electric brakes.

Tip: If you live near Brisbane, book your axle for a set of weld rings. The rest of the installation is DIY.

Fitting electric brakes

The image on the right contains all the components you receive when purchasing an electric brake conversion kit.

Only the bearings and weld ring may change.

You will also require an under-dash brake controller installed, or if you reside in Queensland or NT, a trailer-mounted brake controller complies with the road rules.

In the middle of the picture, the square plate is the most critical part of electrical brake installations.

The weld ring is tig-welded within 0.1mm in the correct location; otherwise, it will overheat.

Tack weld the Brake Mounting Plate into position, ensuring it is square and concentric with the axle.

If the weld ring is out of square or not concentric with your axle, the Electric Brake shoes will wear unevenly, thus reducing braking efficiency.

What is the difference between ‘new’ and ‘old’ brake controller technology?

New technology brake controllers have a proportional brake control unit instead of manual control.

Proportional Electric Brake Controller Installation

The harder you press the brake pedal, the harder your caravan brakes are applied.

New brake controllers have a voltage readout to give the driver a better idea of the brake force applied to the brakes.

- Tow pro elite

- Tekonsha

- Hayman Reese

- Hayes

Please note: All-electric brake controllers should be equipped with a circuit breaker or fuse, which protects against overcurrent.

Manual Brake Control or User controlled.

Old technology brake controllers only apply a preset force or a time delay voltage to the brakes.

Click this link for the article on how to adjust your electric brakes.

Critical steps for brake adjustment are listed below.

Critical Steps – Alko Electric Brake Adjustment

If the weld ring is out of square or not concentric with your axle, the Electric Brake shoes will wear unevenly, thus reducing braking efficiency.

Once completed, you should not be able to see any part of the brake shoe outside the drum.

Note: Different axles use different mounting plates.

12-inch Electric brakes also use different mounting plates.

The popular models are covered here.

Fitting the Electric camper brakes is a matter of tightening four nuts at the back of the Brake Mount plate and then mounting 10-inch Drums and bearings.

Need help about now? Call the experts at Couplemate if you need help now.

There are three types of weld rings.

- Rings with a 44mm round hole fit slimline 45mm to 50mm axles.

- Those with a 39mm round hole fit 39mm and 40mm axles.

- Some have square holes and fit over marine bearings.

Confused? Call us or bring your axle into our workshops for a fit-up.

10-inch Electric brakes have a rating of 1600kg when using 13 – 14-inch Ford or Holden wheels and 1450kg when using 15 – 16-inch wheels.

If you want 1600kg on 15 – 16-inch wheels, go to 12-inch Electrics and 2-tonne drums.

How Electric brake cabling works

Always use a 6mm cable or above when wiring your tandem axle electric braking system. Wire down each chassis rail rather than accessing your axle.

Often, a 3mm or lower cable is used. These sizes are inadequate or marginal and provide sufficient voltage drop from your battery to cause your brakes to work at something smaller than 100% capacity.

If you take the time to upgrade, then do it properly.

For Example, when using a 3mm cable, your controller will be wound up to the maximum voltage.

A voltage drop occurs at the point of the electric brakes, causing you to have only 50% braking capacity. Install a 6mm cable or larger, and you will see a much better result with minimal voltage drop and maximum power at your electric brakes.

After any DIY work is done, you will have your trailer re-certified by an approved inspection station.

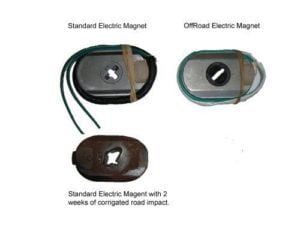

Rough dirt roads cause magnet damage.

Electric Magnet Comparison

What is the difference between Off-Road, Highway and Budget Electric Brakes?

(a) Budget Electric Brakes are ideal for tandem trailers, horse floats, and other similar trailers that perform short-haul duties.

(b) Standard Highway Electric Brakes are common on caravans and campers. Brake shoes and magnets are of a higher grade to dissipate heat generated by long haul on Australia’s highways.

(c) Off-road driving can get hot and dusty. Standard-duty electric brakes can get highly overheated because dust, sand, etc., build up inside the electric brakes. Off-road electric brakes are designed to cater for the effects of off-road travel. Better shoe material and anti-rattle electric magnets make off-road brakes a must for the serious traveller.

Off-road magnets have plastic inserts to help prevent magnet wear caused by road corrugations.

If electric brakes are installed with standard electric backing plates, the magnets rattle on the magnet-actuating arm, causing the magnet lever arms to wear and fail.

Read our Caravan Electric Brakes FAQ here.

BASICS (legal stuff)

- Trailers with a total laden weight under 750kg do not need brakes.

- Trailers with a total loaded weight between 750kg and 2000kg need brakes on one axle. Disc brakes, Mechanical drum brakes and electric brakes are acceptable.

- Trailers with a total laden weight between 2000kg – 4500kg need electric brakes or electric/hydraulic on all axles, plus a breakaway kit.

- A trailer is any vehicle with wheels connected to your tow vehicle and towed.

Zero to 750kg Trailers

Small trailers up to 750kg do not need brakes.

Always buy your hubs from reputable dealers like Al-ko and a few others. You do not want hub and flange separation from poor-quality hubs below.

750kg to 2000kg Trailers

- 10-inch disc rotors are the cheapest type of brake system you can install.

- Welding a caliper mounting plate onto your axle would be best, and the hard part is over.

- When buying a new trailer or caravan axle, ask your retailer to arrange to install the calliper anchor plate.

Caravan and trailer disc brakes engage when the tow vehicle’s override coupling activates during braking.

When the tow vehicle brakes, the trailer pushes into the tow vehicle and enables the override assembly to pull the cable attached to your disc callipers.

All override couplings have a slight time delay. Use disc braking systems on boats and tandem trailers. Disc brakes are not ideal for camper trailers unless you do a lot of sandy driving on beaches.

What are the different types of trailer Braking Systems

- 9-inch Mechanical Override brakes work like disc rotors, except you need to weld a ring onto the axle to hold the brake backing plate. It is a little more expensive than disc rotors and is suited for small caravans and trailers.

- 9-inch Hydraulic Brakes work on an override assembly, except the cable is replaced with hydraulic lines and is mainly used on older caravans and tandem trailers.

- 10-inch electric brake systems use a four-hole weld ring to secure the 10-inch electric backing plate to the axle. Once the backing plate is attached to the weld rings, the drum is fitted and tightened with the axle nut. 10-inch Electric brakes are suitable for any axle up to 50mm in diameter. When adjusting the axle nut, tighten it as much as possible, then back off the 1/8 turn.

- 12-inch Electric braking systems suit 50mm and above axles. Loads over 1600kg on a single axle will require 12-inch braking systems.

How is axle capacity determined?

Axles for trailers, caravans and campers are rated according to the bearing size.

The size or diameter of the axle does not determine the maximum axle rating. However, some longer axles are derated. They are also derated on 39mm Round and 40mm square axles where offroad tyres are installed.

Maximum axle capacity loadings are as follows:

- 750kg – 39mm Round Axle,

- 1000kg – 40mm Square axle,

- 1600kg – 45mm Square Axle.

- 3000kg – 50mm Square Axle

Maximum Tandem setups for 45mm Square and round, rated at 2900kg for 10-inch Electric Brakes. If it is over 2900kg on a tandem, you will require 12-inch electric trailer brakes.

39mm Round and 40mm square axles are derated by 20% when using offroad tyres. Further, these axles are derated by 20% for lengths over 2100mm

2900 – 4500kg needs 12-inch electric brakes that are 50mm to 65mm round, depending on weight requirements.

Once you have decided what weight to carry, it will select the right axles, brakes, and spring setups.

What is the most common setup? Electric brakes on campers and caravans.

Correct Axle Setup

Question: I am building a trailer and want a complete setup under 750kg to go to Cape York.

Answer: The cheapest solution is a 45mm Round axle rated at 1450kg with heavy-duty springs and 6 Stud lazy hubs.

You can install brakes later if you need them. A setup with a lower rating will give you trouble, as you will almost certainly carry more weight than you predicted.

Water, Fuel, Food, gear, etc., will add more weight than you think to your total trailer weight.

Weighbridge Certificate

Question: My boat trailer is about 2 tonne tandem with 50mm Square axles and brakes on all axles, which no longer work. I purchased the trailer and boat cheaply, but the trailer needs work. I need disc brakes on one axle because the weight is close to the limit.

Answer: A trailer and a boat will almost certainly weigh over 2 tonnes, and you must get a weighbridge certificate.

This certification is required to get it registered in your name, so I suggest that you weigh the rig so you are not throwing money at a brake setup that you may be required to upgrade.

You’ll save a lot of money in the long run by having the proper setup the first time.

Why do Electric Brakes fail to work?

Question: I purchased a set of Electric brakes and had them installed. When the brake controller turned to full power, my caravan brakes did not lock the wheel.

Answer: (a) Check the electric brake wiring and ensure the cable installation is 3mm (minimum) for single axles and 5mm for tandem axles. Using smaller cable sizes may cause a problem with voltage drop.

(b) The brake shoes may not have bedded themselves if you have not travelled 100klms – 150 km and readjusted the brakes.

(c) Apply 12 volts to the brakes; you cannot move the wheel. If the direct method works well, your electric brake controller may have a problem.

(d) Most trailers do not incur wheel lock except for an empty load.

(e) A voltage drop occurs when you use too much cable. For Example, an axle is wired across the axle. Two ways to fix it. (a) Rundown each chassis rail and wire to each brake. (b) Run a larger size cable across the axle.

Read our Caravan Electric Brakes FAQ here

Hot Electric Brake Drums?

Question: My brakes get hot even when the brake shoe adjustment is loose, and the electrics are disconnected.

Answer

- Remove the drum and inspect the shoes. One or both shoes may be out of the centre: Re-centre shoes and reinstall the drum.

- Reinstall the brake drum, and adjust the shoes tightly until there is no more adjustment.

- Check voltages on each magnet with the engine running to replicate running conditions. The last magnet may be lazy and cold because it is not receiving sufficient voltage. The brake on the other side of this axle will get hot because it is doing double the work. The solution is to increase the size of the cable.

Then wind the adjustment lever 13 clicks. The factory setting is 13 clicks from the locked position.

Electric brakes get hot when first installed because the shoes are not aligned correctly, and the drum is on one end of either or both shoes.

(c) Another reason is that Chinese Bearings are getting hot, so they are being replaced with Japanese ones.

Correct Caravan Bearings

Question: I purchased my caravan bearings from a reputable shop. How do I know if they will cope with long trips?

Answer: We do not support any single brand of bearing.

The word JAPAN must appear on the bearing to ensure you have a quality long-haul bearing. If the word JAPAN is not on the bearing, I will not use them.

The Electric Brake Controller is not Working.

Question: I installed my tandem electric brakes using a chassis-mounted controller, but my brakes are locked on.

Answer: Once your brakes are under load, they will perform like new. If your trailer is empty, your brakes will likely lock on some road surfaces.

When everything you have tried fails, read this groundbreaking article on ineffective brakes.

Furthermore, Advice on this page is obtained from some sources, not necessarily our own.

Finally, using any text or images on this page is forbidden by law unless you provide a link back to this page on your page.

If you found this article informative, feel free to leave a comment.

Electric brakes made simple

© Steve Wotherspoon 3rd May 2014, updated January 2020

Very usefull information, thank you.

Editors Note: Love to hear your comments whether you found the article helpful or perhaps some things may need to be added to make it more informative.

Good article but so confused.

I have recently bought a tandem builders trailer (new) from a Gold Coast company. It has slipper springs with 40mm square axle with 185/14 tyres 5 stud ford I think. I have no end of drama with the brakes. Firsty I think they are cheap ebay brakes. They have also used standard 7 core to power and earth the brakes and have wired up to the left axle then over the axle to the right side.

When they were working I could wind the tow pro elite up till the wheels would lock up but would barely notice any braking force.

I’d like to upgrade to a 12″ off road as I’m a rural builder and most of the jobs I work on are rough dirt roads and some require 4wd low to gain access.

Am I able to run 12″ off road on a 40mm square axle and will one axle be sufficient. I also want to fit my standard hilux rims (6 stud 265/75/15) to the trailer.

I live in Toowoomba. Are you guys in Brisbane. If I get the trailer rewired front to back with 8mm guage to the brakes will you fit the 12″ brakes or only supply them.

Thanks Brendon

Hello Brendon,

Many thanks for the query. Let’s get right into it.

Your 40mm square tandem axles have a maximum rating of 2,000kg; however, your braking capacity is 1600kg. So there is plenty of braking available.

The 7 core cable is almost certainly undersized. Your tow pro elite is ok.

12″ brakes would not work on your axle; however, you could change over to offroad electric magnets on your existing brakes. BTW, your existing brakes are ok.

You could, of course, upgrade to 45mm square axles, but only if you are over the 2,000kg limit.

Rod is an expert, and I am sure you will be happy with his work.

Thank you

Steve Wotherspoon