10-inch Electric Brake Magnets suit Dexter Brakes and AL-KO Brakes

Caravan standard 10-inch electric brake magnets are suited to all-electric brake systems except for older round magnet brake systems.

These magnets create a magnetic field that pushes against the drum when an electric current is passed through them.

This, in turn, engages the trailer brakes and brings the vehicle to a stop. The size is of crucial importance as it determines both the strength of the brakes and how much power is needed to activate them.

These magnets are commonly used in heavy-duty trailers and can vary a range of sizes to match the specific requirements of different vehicles and loads. Proper maintenance and replacement of these components can help ensure safe and reliable trailer braking performance.

What maintenance checks should I perform on my electric brakes?

How to check magnet wear

- Check the four small holes on top of the magnet.

- These holes are warning indicators that display magnet wear.

- Extreme magnets wear if there are no holes or fewer than four holes.

- When the face of the magnet hole has worn, then it is time to replace the magnet.

Magnet Wear Key Features

- Wear holes are at 3 pm, 6 pm, 9 pm and 12.

- Magnets draw approximately 3.2 amps each.

- Wires can be connected either positively or negatively.

Once worn, copper begins to become exposed. Subsequently, an open electric circuit will render the brakes inoperable.

Braking Tips

- Bed new magnets into position to achieve 100% braking efficiency.

- The magnet face is a shiny finish.

- This finish must be scuffed up during the initial stages of breaking before your magnets become 100% captive.

Why can’t I run the electric cable across my axle?

Voltage drop increases exponentially according to the length of the cable. Voltage drop is defeated with larger cable or shorter cable lengths.

- Rundown each chassis rail = 6mtr @ 6.4 Amps per pair of magnets = 5.62mm cable size

- Run down the chassis trailer (inside) = 6 meter + 2 mete (8mtr) @ 6.4 Amps per pair of magnets = 7.5mm cable size

To escape voltage drop, run the cabling down the chassis rail.

What is the best Electric Brake Controller?

We recommend using a Tekonsha Primus, Prodigy, or a Chassis Mounted brake controller (Qld and NT Only).

Do not power electric brakes from the brake light circuit for chassis-mounted brake systems. Incandescent brake light circuits provide 21 watts of power and perform the function of a control circuit for chassis-mounted controllers. If you have purchased a caravan or camper with brakes wired into the brake lights, the braking system works at less than 25% of its efficiency.

Wire all brake controllers from the battery. In most cases, the brake controller has a relay powered by the brake lights.

Brake Controllers use Brake Lights to Power Brakes.

If brake lights are used to power brake controllers, significant voltage losses will occur, resulting in brakes operating at less than 25% capacity.

Brake magnets need 3.2A each. The manufacturer wires no vehicle to supply this load through rear tail lights.

It is permissible to wire chassis controllers from the onboard battery in the caravan.

Why do off-road magnets last longer?

- The steel magnet arm causes the steel magnet on a standard highway magnet to rattle, causing wear.

- The plastic insert on the off-road magnet prevents the same wear under the same conditions.

The 10-inch Off-Road Electric Brake Magnet is designed and extensively tested for harsh Australian conditions. It is durable and reliable and will not disappoint even in the most challenging terrain.

What is the difference between on-road and off-road electric brake magnets?

Difference between Highway and Offroad Magnets

- The Electric Highway brake kit uses a magnet retaining clip to hold the magnet into position on the arm.

- Off-Road Electric brake magnet uses a RUBBER BAND to hold the magnet into position on the magnet arm.

The rubber band breaks on first use and relies on the return spring to hold the magnet.

The left-side and right-side magnets are not interchangeable.

- The left hand is the passenger’s side

- The right hand is the driver’s side

The purpose of the rubber band is to hold the magnet into position to allow drum installation onto the axle profile, then tighten.

If the magnet needs replacing or upgrading from a standard magnet, then replacing the whole backing plate may be wise.

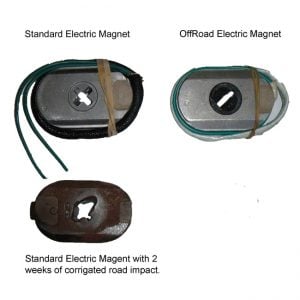

Electric Brake Magnet Comparison

The magnet in the third image was a standard magnet used on corrugated.

All 10-inch OffRoad Electric Brake Magnet have a plastic insert that prevents the magnet arm from causing damage to the magnet from corrugated road vibrations. (Image 2).

As a result, offroad magnets continue to show no wear tens of thousands of miles on corrugated roads.

Safety Chain Checks

Necessary safety checks or tandem wheel caravans. With the chains attached to your vehicle, push your trailer back to the extremity of the chains.

Review associated products here

- Electric Brake Shoes

- 10-inch Electric Backing Plate Brake Kit

- 10-inch Electric Drum with Bearings

- 12-inch Electric Backing Plate Brake Kit

- 2t Electric Brake Drum, Incl Greased Bearing Kit

- Cruisemaster 2t Drum incl, Greased Bearing Kit

Finally, did the pin on your breakaway kit disengage? Learn why.

Additional information

| Weight | 0.4 kg |

|---|---|

| Dimensions | 8 × 5 × 3 cm |

| Electric Magnet | 10-inch Budget Electric Brake Magnet, 10-inch Electric Brake Magnet, 10-inch Offroad Electric Magnet Left, 10-inch Offroad Electric Magnet Right, Dexter Aftermarket Magnet, Dexter Electric Magnet |

Reviews